Explosion-proof cameras play a crucial role in hazardous environments where the risk of explosion or fire is present, such as oil and gas refineries, chemical plants, and mining sites. These specialized cameras are designed to withstand and prevent explosions, ensuring the safety of personnel and critical infrastructure. However, selecting a suitable explosion-proof camera requires careful consideration of various factors. In this blog post, we will provide a comprehensive guide to help you choose the right explosion-proof camera for your specific needs. From understanding industry requirements to evaluating camera specifications and certifications, we'll cover everything you need to know to make an informed decision.

Section 1: Understanding Industry Requirements

· Regulations and Standards: Familiarize yourself with local and international regulations, such as ATEX, IECEx, or NEC, that govern explosion-proof camera installations in your industry. Understanding these requirements will help you make informed decisions when selecting the appropriate camera.

· Hazardous Area Classification: Determine the classification and zone ratings in your facility or industry to identify the level of explosion risk. Different zones require cameras with varying levels of protection against potential ignition sources.

Section 2: Camera Specifications and Features

· Explosion-proof Construction: Look for robustly constructed cameras that can withstand extreme conditions. Features like heavy-duty enclosures, impact resistance, and corrosion resistance are essential for ensuring the camera's durability.

· Temperature Tolerance: Evaluate the camera's temperature resistance to ensure it can operate safely within the expected temperature range of your hazardous environment.

· Optics and Image Quality: Consider the camera's optics, including lens type, focal length, and resolution. Adequate image quality is crucial for capturing clear footage in hazardous environments.

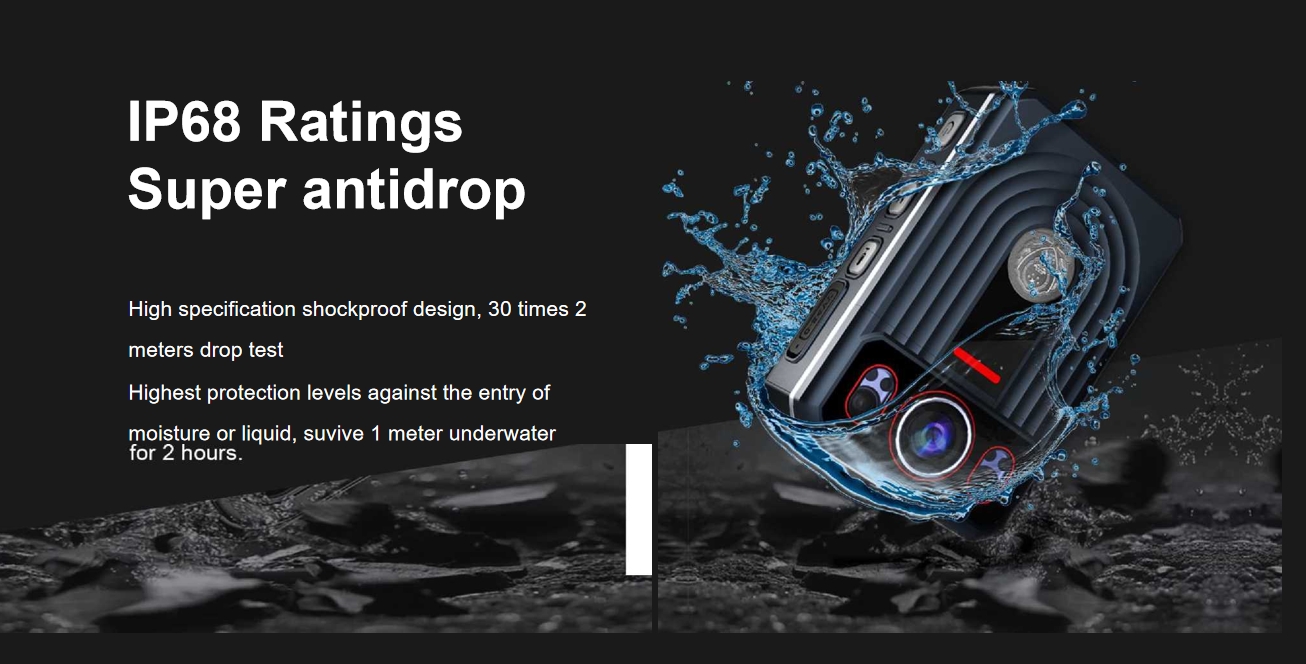

· Ingress Protection (IP) Rating: Check the IP rating of the camera to gauge its protection against dust, moisture, and other environmental elements. Higher IP ratings indicate better protection.

· Night Vision Capability: For applications requiring 24/7 surveillance, choose a camera with infrared (IR) or low-light imaging capabilities to ensure visibility in dark or dimly lit areas.

· Video Analytics: Explore if the camera offers video analytics features such as motion detection, object tracking, or facial recognition, which can enhance security and situational awareness in hazardous areas.

· Network Connectivity: Ensure the camera supports the required network protocols (e.g., Ethernet, Wi-Fi) and consider if Power over Ethernet capability is desired for simpler installation and maintenance.

Section 3: Certification and Compliance

· ATEX and IECEx Certification: Look for explosion-proof cameras with ATEX and/or IECEx certifications. These certifications validate compliance with European and international explosion protection standards, respectively.

· NEC Class and Division Ratings: If you operate in North America, verify if the camera meets the specific National Electrical Code (NEC) Class and Division ratings required for your hazardous location.

· Certified Temperature Range: Ensure the camera's operating temperature range is compliant with the certification requirements, considering the lowest and highest expected temperatures in the hazardous area.

· Certification Documentation: Request and review the camera's certification documentation, which includes detailed information about the device's suitability for explosive environments.

Section 4: Integration and Compatibility

· Compatibility with Existing Infrastructure: Assess whether the camera can integrate seamlessly with your existing security systems, video management software, or network infrastructure. Compatibility is crucial for streamlined installation and efficient surveillance management.

· Power Supply Options: Consider power supply options such as AC, DC, or Power to ensure compatibility with your facility's power infrastructure. Select the option that best suits your operational requirements.

· Storage and Retrieval: Assess how the camera handles data storage and retrieval. Explore if the camera supports local storage or if it leverages a centralized storage system for efficient data access and management.

Section 5: Installation and Maintenance

· Mounting Options: Evaluate the available mounting options suitable for your environment, whether it's wall, ceiling, pole, or explosion-proof housing installation.

· Ease of Installation: Choose cameras with installation features like adjustable brackets, quick-release mechanisms, or user-friendly interfaces to simplify the setup process and reduce installation time.

· Maintenance Requirements: Consider the maintenance needs of the camera, including factors like cleaning procedures, firmware updates, and availability of technical support from the manufacturer or vendor.

Selecting a suitable explosion-proof camera is critical for maintaining safety, security, and regulatory compliance in hazardous environments. By understanding industry requirements, evaluating camera specifications, certifications, and compatibility factors, you can make an informed decision that aligns with the unique needs of your facility. Taking into account aspects such as explosion-proof construction, temperature tolerance, image quality, certification compliance, integration options, and ease of installation and maintenance, will ensure you choose a camera that enhances situational awareness, minimizes risks, and provides reliable surveillance in hazardous areas.

French

French German

German Arabic

Arabic Italian

Italian Spanish

Spanish Japanese

Japanese Persian

Persian Korean

Korean Chinese (Simplified)

Chinese (Simplified)